AEV’s JK Tubeless Front Bumper now takes its place as the industry’s second stamped steel bumper – behind AEV’s original JK Premium Front Bumper. It also receives an OE-level double stage paint process to help keep Mother Nature at bay.

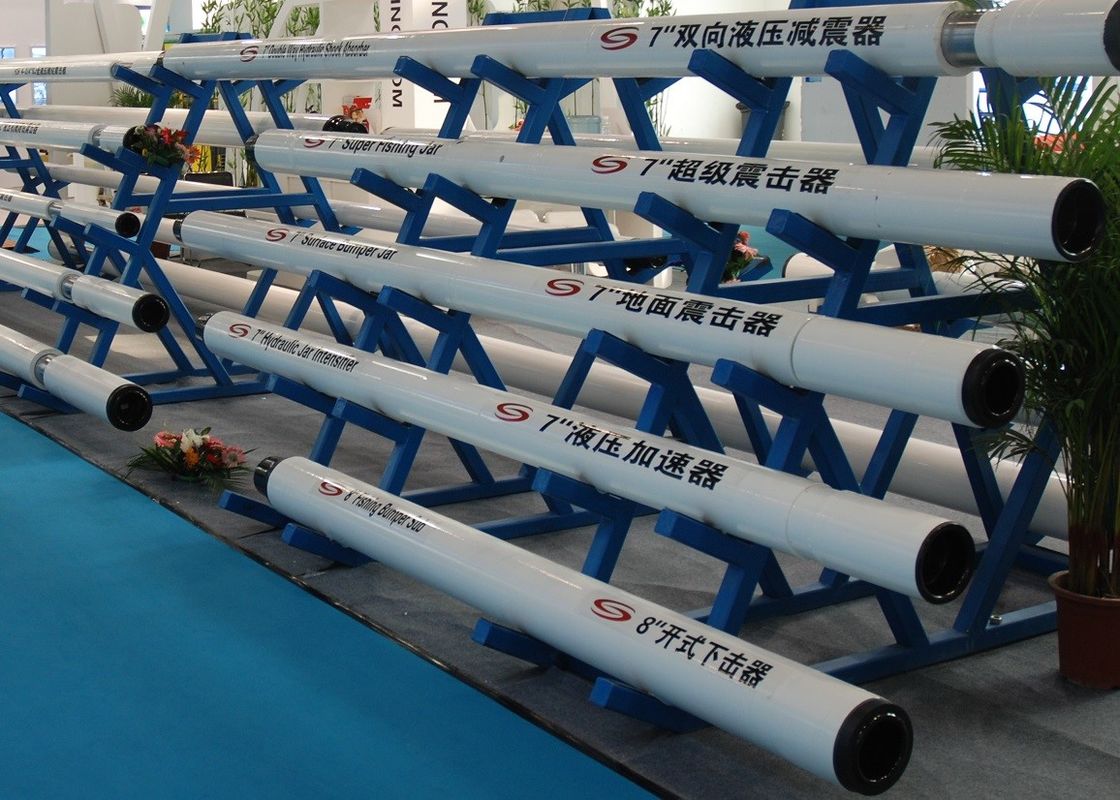

The AEV JK Tubeless Front Bumper includes auxiliary light mounts, factory fog light mounts, and crush cans to help correct low speed airbag deployment. Others: Air winch Drilling line Safety equipments Mud pump spare parts Rig parts Fittings ect.Based on the tried and true design of our Premium Front Bumper, the stylish stamped steel face of the AEV JK Tubeless Front Bumper is built to withstand all the rocks, mud and brush you can throw at it while providing a very sleek, sophisticated look. Cement tools: Cement unit Float collar Float shoe Liner hanger Cement head ect.ĩ). Downhole/Fishing tools: Drilling & Fishing jar Stabilizers Hole opener Overshot Drilling bit ect.Ĩ). Tubular Running and handing tools: Elevator Slip Manual/Power tong HPU Bushing Spinner Bit breaker Spider Links Stuibing guide Thread protector ect.ħ). Tubulars & Drilling strings: Drill pipe HWDP Drill collar Kelly Casing Tubing Pup joint Sucker rod Line pipes ect.Ħ). Solid control & Mud system equipments: Shale shaker Desander Desilter Mud cleaner Hopper Centrifuge Agitator Mud tanks Unions,ect.ĥ). Wellhead & Pressure control equipments: BOP Chock & Kill manifold Pressure hoses BOP closing unit Casing&Tubing head X-Mas tree Valves Spools and flanges ect.Ĥ). Rig components: Crown block Travelling block Hook Swivel Rotary table Drawwork Driller 's cabin MCC/SCR house MCC/VD house Top drive ect.ģ). Rig packages: 250hp to 3000hp Land drilling rigs Workover rigs(Fast-moving rigs are available).Ģ). Our main range include but not limited below:ġ). SEACO Oilfield Equip,is manufacturer & stockist of equipments,services and solutions to the upstream to downstream in oil & gas industry.We are aimed at helping customers to obtain the maximum from their each well.Providing our customers superior quality at the best value for products and services in order to ensure our customers ' continued satisfaction. Longer stroke length will provide a bigger jarring force. Longer length of spring extension during lifting will provide a greater jarring force. Higher hanging weight will create higher jarring force.Length of spring extension of the drill stem. Hanging weight on top of drill stem with the bumper jar. Main factors that influence the jarring force At this instant, both released energies combine, creating a large downward jarring force. As the drill stem accelerate downwards, the bumper jar is released towards its closed position, releasing its potential energy.

Sudden release of the lift load will convert the stored strain energy in the drill stem to a downward acceleration force. As more lift load is applied, the drill stem begins to accumulate stored strain energy due to the spring extension.

When lift load is applied to the drill stem, the bumper jar is pulled open to a certain height creating a potential energy. When the bumper sub is used with a reversing unit, it helps to compensate the rising stroke for threads after reversing.ĭownward jarring forced is achieved through the conversion of stored energy to kinetic energy. In milling and cutting operations, the bumper sub is used to provide feeding force to the mechanical internal cutter, ensuring a reliable and even cut. In event where stuck drill stem cannot be released by lifting and jarring, the bumper sub can be rotated to engage and disengage releasable fishing tools to release the fish. It allows operators to bump up or down repeatedly until the fishing objectives are met or when the stuck drill stem is released. KXJ type bumper sub is a mechanical jarring tool.

0 kommentar(er)

0 kommentar(er)